It was pointed out to me the other day that though I spend far, far too much of my time in person talking about 3D printing with everyone and anyone who will listen to me (and some who really don’t want to …1), I really haven’t posted much at all about it online.2

Table of Contents:

Introduction

I have been interested in the idea of 3D printing since at least … college? I feel like one of my physics professors talked about some early 3D printing stuff in the very early 2000s. This was a man who talked fondly of the early IRC days and has now left academia to go be a financial quant, so he’s definitely the type.3 But, the early days of 3D printing were, frankly, awful. Printers were projects in and of themselves, not for projects. Then I became a public servant, and we all know how well that pays so 3D printing seemed like an expensive (resources and time) hobby that I couldn’t really afford to get into.

Making always seemed really cool, but I’d never really worked with my hands very much. Taking band in Hood River meant never being able to take shop, and my dad did most of his woodworking long before kids, outside of redoing the flooring in our house with laminate. I knew people who were skilled tinkers4 and had the seemingly magical ability to turn their thoughts into objects in the real world, and a brother who is a skilled sculptor, but it wasn’t a thing I thought *I* would ever be able to do.

Then I bought a house, and realized how expensive it is to pay someone to work on one. Youtube convinced me that I could replace my own toilet … and it turned out I could. It wasn’t even very hard.

Then I decided I wanted a wine cellar in my basement … and I, who had never even made a birdhouse before, designed and built a wine cellar from scratch.5 It’s … over-engineered. I joke that if we have an earthquake, I’m hanging out in the wine cellar for safety. It’s only kind of a joke.

Over the last few years I’ve built some custom furniture (a crate for Denali, a bourbon shelf for the wine cellar, a custom shelf for the spot behind the door in my bathroom, display shelves around my office, the dining table on my deck, etc.), rebuilt my back deck, and added a lean-to to that deck during COVID, but I would say with very few exceptions I build thing that are functional first and aesthetic second, if at all.

Then I lost my job, and had a LOT of free time suddenly.

I decided that I needed some Funemployment principles, and one of them was that I needed projects. I needed to keep busy, mentally and physically, and I needed some mental challenges to intersperse with endless job applications. I thought, I enjoy woodworking, and I have a collection of headphones; why not combine the two and build a custom headphone stand worth of the single most beautiful possession I have, my beloved Bokeh. It was going to be a new thing, building something to be functional AND beautiful, so I thought it was time to join the local maker space, OlyMega, to get some help with the new skills I needed to develop. I showed up to the next Thursday night open house, and ended up having a conversation about the 3D printers scattered around the room. They were available, for anyone to use. It was … a revelation. After all, you can make headphones with a 3D printer.6 I did finish the stand project (and I’m very proud of the results), but quickly the obsession turned to 3D printing.

I’m not great with my hands. I can make things that function, that fill a need. I’ve never been the guy who can make things that are pretty. (That was always Dylan in my house.7) I have a strongly visual memory and brain, and I’m good at both spatial reasoning and analyzing how objects exist and interact, but that has never translated into making something. 3D design, however, lets me think and build with polygons and design and redesign and adjust and prototype. It turns out this plays to my strengths. Which, honestly, maybe shouldn’t be surprising? My favorite class in high school was Drafting,8 and I really did think I’d end up as an engineer.

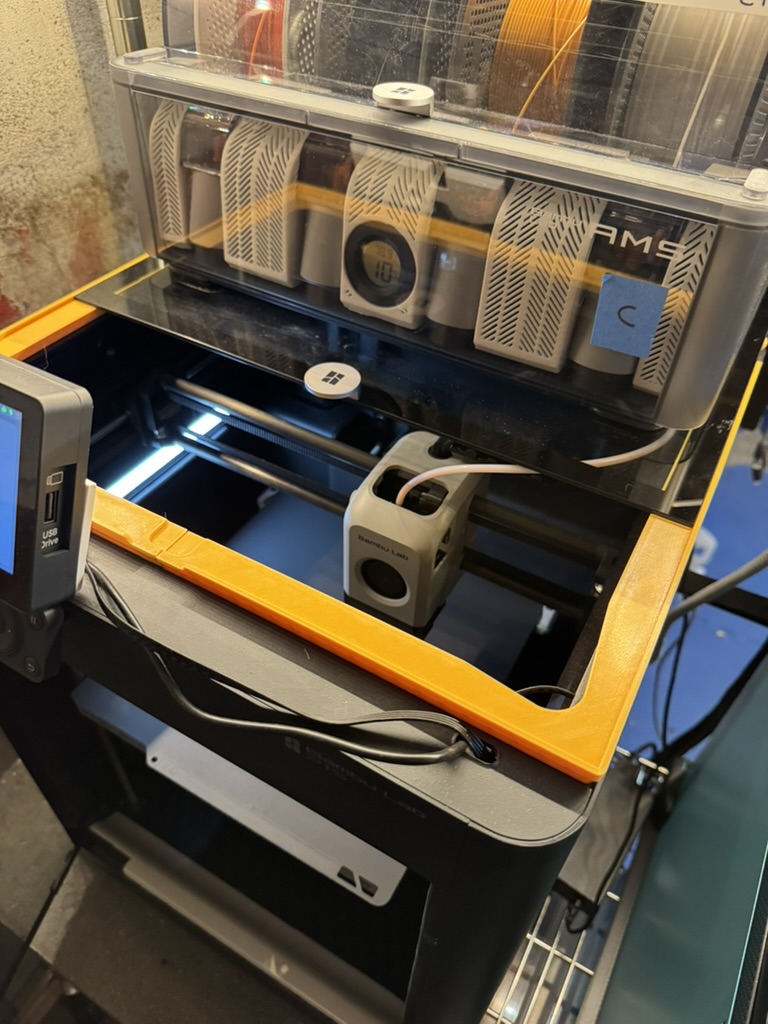

It was great. I picked a bunch of projects, broke them down into one or two hour chunks, and started printing them a piece at a time when I was in the space. But … then I got impatient. I got a job!9 I had made a deal with myself that when I got a job, if I hadn’t used my entire severance, I’d buy myself a good pair of headphones as a celebration. I decided to change it up and buy myself a 3D printer instead, and build the pair of headphones. After some research, I went with one of the options I’d been using at OlyMega, the Bambu Labs P1S.10 And I loved it. And love it. And the journey continues.

The Prints

There’s that old bromide that everything is a nail to a hammer. And, as it turns out, everything is a 3D project to a man with a 3D printer. I think of my prints as falling into three big categories:

- Functional prints.

- Fun prints11

- Gift prints

Functional Prints

There are two kinds of people in the 3D printing community: 1) people who love 3D printing, and 2) people who love 3D printers. The danger of buying a 3D printer is that the printer becomes the project, rather than a tool to complete projects. And I certainly fell prey to this for a bit; the first half dozen prints I did were all things to increase the productivity of my printer, rather than actual prints for their own sake. Some of this is intentional; Bambu wants you to print a Benchy (a model tugboat that tests a bunch of functionality), a scraper handle (for the included razor blade), and by default the P1S spits its poop (the filament it ejects when loading, unloading, or changing its materials) out the back with no receptacle, so you need a poop chute if you don’t want your floor covered with bits of plastic.

But, in the end, I bought my printer to make stuff, not to optimize a printer.

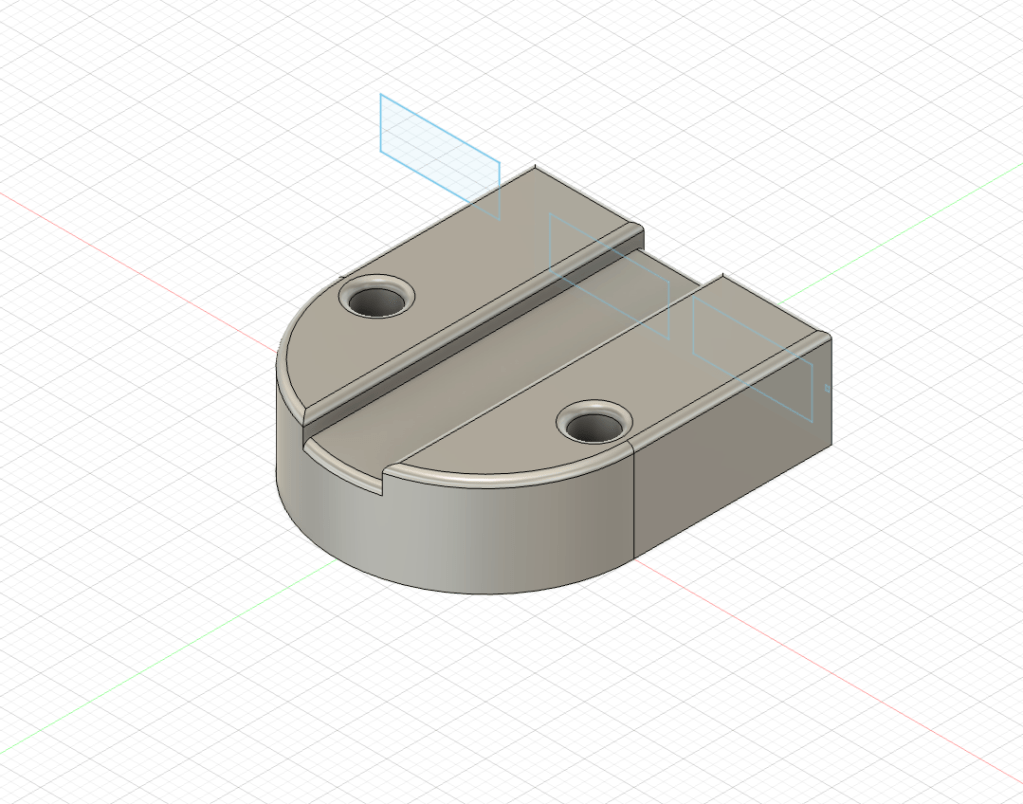

Up front, I didn’t do as much functional printing as I expected. The thing about functional prints is that they’re largely pretty specific and adapted for your particular situation. Like a lot of 3D newbies, I mostly stuck with other people’s designs up front. As I got more comfortable with the software (and the hardware), I started doing some customization.

My printer(s) live in my basement, which has six light bulbs on the same circuit, in four functionally different areas. Rather than paying an electrician to break up the circuit, I opted to use a series of Philip Hue lights (which I use in my living room, office, upstairs, and bedroom) to give me more control over where I have light. BUT, I found it basically impossible to stop hitting the switch every time I walk into the room. So, I took an existing design for a outlet cover for a light switch and modified it to 1) cover the existing light switch and 2) let me mount a Philips Hue switch:

Is it perfect? Heck no! If I hit it too hard, the plate slips off of the outlet frame, and the magnet isn’t the best way to keep the smaller switch mounted. Would I do it this way if I did it today? Nah; I’ve got some ideas on how I’d change it if I did it again today. BUT: it WORKS. I walk into the basement and I hit this switch instead of flipping off the entire circuit.

These are honestly the most fun kind of print for me; there are usually some things on one of the various STL websites that are close, but they almost always require some adjustments and development. There’s something about measuring, designing, and rapid prototyping that scratches a very specific itch in my brain. I’ve done a bunch of these at this point: under-desk drawers, headphone hangers, a Multiboard12 for my office, guards for my mom’s stove to avoid her (or her dog) from bumping the burners on, screw sorting bins/cases, and a variety of little plastic cases for specific applications.13

And, of course, because I’m me, I’ve figured out how to make headphones … and made a bunch.14 Seven variations on give major models, so far. Are they the best headphones I’ve ever heard? Nah, I’ve got a pretty good collection. But are they really good-sounding, particularly when you consider how much I paid for parts and printing? Absolutely, and honestly I’ve been listening to the Golem-modded Ouroborous more than anything over the last few weeks.

I’ll do reviews of these in the coming weeks, but both of the open-backs (the Capra Audio Satyr 3 and the DMS Open Omega) are really excellent implementations of $10 drivers, and the closed backs (Ouroboros, Golem-Modded Ouroboros, and Oreoboros) are truly excellent, particularly given that they use drivers stripped out of an pair of pretty lousy gaming headphones.

Fun Prints

One of the first things I did after I did a bunch of quality of life prints was start printing fidget toys, starting with a crystalline dragon. It also turns out that many of my friends, and their kids, and their nieces and nephews are big fans of little plastic things so I’ve had a grand ole time printing a variety of toys and art projects. Whether they’re tiny highland cows, dragons, fidget spinners, or Magic: the Gathering paraphernalia.

Some are more “practical” than others, but they’re pretty much all a good time.

Gift Prints

It’s also just plain fun to make things that other people will enjoy. My girlfriend has a couple of adorable cats, so I have done fun prints of them (and Denali!). My best friend designs table top games, so I’m helping him with developing dice.

The Process

You can, of course, spend thousands of hours printing without ever doing any designing yourself. There are a dozen websites that collate .STLs15 and .3mfs16, either free or for small fees for the artists, and my experience in this community is that people are incredibly generous with their time and assistance if you run into issues. That said, I think it’s worth learning at least a little bit about how to manipulate objects, and while it’s a little intimidating right out of the gate, it’s not as complicated as it may seem at first. I started by working within Bambu Slicer (the tool that Bambu provides), which gives you very basic options like increasing/decreasing sizes, changing colors (if you have the right filament), and adding and subtracting basic polygons (cubes, cylinders, etc.), and it was a lot of fun. At some point I moved to Fusion 360, a free-to-consumers 3D modeling tool that lets you start with 2 dimensional sketches and turn them into 3D objects you can then make in the real world.

There’s just something magical about taking a thing in your brain and turning it into an object in the physical world. As a person who has always admired and been a bit envious of artistic people who are able to express themselves through drawing or sculpture or other art forms, this lets *me* do that same thing in a different, brain-itch-scratching way.

Conclusion

I’ll be doing reviews of my various 3D printers over the next few weeks. I have enough experience under my belt with the various Bambu offerings that I have some pretty strong feelings and recommendations, but for anyone who is interested in this space, it’s a pretty fun one. Just … make sure you order more filament than you think you’ll need.

Much more.

So, so much more.

- Sorry, Kristi. Love ya! ↩︎

- Well, at least outside of Reddit and a couple of 3D printing groups/forums. It’s probably displaced audio as the top topic of discussion for me. ↩︎

- Also I think an Australian champion ballroom dancer? But I might be making that part up. Suuuuper interesting guy, as much as a couple of his classes drove me crazy. ↩︎

- Hey Robin! Howdy, Lane! ↩︎

- Including custom shelving units. ↩︎

- To the shock of precisely zero people. ↩︎

- Seriously, he made a copper scultpure in college that I think about at least once a month with avarice in my heart. ↩︎

- A mix of AutoCad and manual, pencil drawing. Brennan and I have nothing in common other than his having help design my childhood home, but that class scratched a VERY specific itch in my brain and I think about it regularly a quarter century later. ↩︎

- It’s awesome. ↩︎

- I’ll do a review at some point. ↩︎

- I.e., mostly headphones. ↩︎

- A specific category of pegboard built around a hex system rather than pegs. It’s … complicated but pretty cool? ↩︎

- A remix of which became my (so far) most downloaded 3D model on Maker World. ↩︎

- Are these really functional prints or fun prints? I’ll leave that to you to decide. ↩︎

- The file format for individual objects or groups of objects. ↩︎

- The file format for a project. ↩︎

Leave a comment